Moody Corporation provides high-quality metallurgically binded weld depositions services. Alloys commonly utilized include Cobalt Base (STELLITE® 1, 6, 12, 21, 156) and Nickel Base (DELORO® 40, 50, 60;COLMONOY® 5, 6; INCONEL® 625).

Other alloys available include the Carbide Alloyed materials, high quality Iron Base metals, and Intermetallics (STELLITE® TRIBALLOY®)

Methods of deposition include Plasma transfer Arc; TIG; MIG; SMAW; and Oxy-Acetylene.

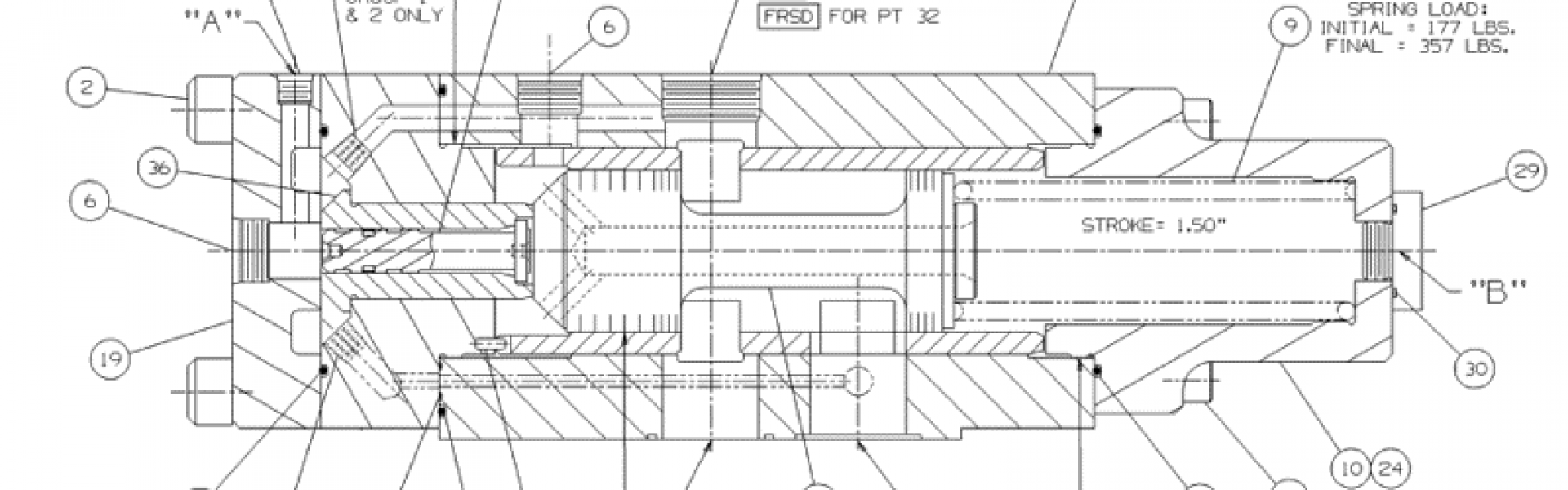

Overlay deposits are of low dilution; defect free; high density; and can be applied to substantial thickness. Large ODs; small IDs down to 1-1/2 inches; and compound shapes are readily accepted. Coatings can be expected to exceed industry standards as to quality of deposition.

In addition, we offer light to medium components (up to two ton) fabrication services. Complex assemblies requiring subsequent overlays, machining and/or precision fitting are our specialty. Welding procedures are qualified to ASME, AWS, Military or customer specifications.

Areas of current and potential application include:

- Valve parts including cages, discs, backseats, seat rings, balls, stems, guides.

- Weld overlay coated exchanger tubes and tube sheets.

- Turbine bell seals, shafting, valves and vanes.

- High pressure pump shafts, sleeves, impellers, and couplers.

- Prototype metals development and deposition (availability in powder mesh characteristic form required).